Blanke Aqua Keil 8442856125R gradient edge profile 2000x12,5x40 right Stainless steel satin black

General

- Blanke Aqua Keil

- 3 - 4 weeks

- matt black

SHOWER DRAIN

- 2000mm

- Stainless steel

- 12,5mm

- right

Blanke Aqua-Keil gradient edge profile

For the perfect detail solution on sloping surfaces to connect with flooring with linear drainage: the BLANKE AQUA-KEIL. The stainless steel gradient edge profile is available as a left or right version.

The perfect finish: the deep-drawn moulded part BLANKE DIBA-KEIL or BLANKE DISK-KEIL for reliable waterproofing of the transition from screed to the wall.

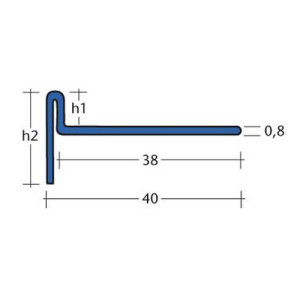

h1 = 12,5mm

h2 = 40mm

Characteristics

- Easy to install – slope of 2 % included

- Protective

- Decorative

- Save time

- System product for BLANKE DIBA-LINE+

Description

- BLANKE AQUA-KEIL is a gradient profile in stainless steel for a slope of 2 % which can be used as an optical access for linear drainage.

- BLANKE AQUA-KEIL is available in left and right versions.

Aplication area

- BLANKE AQUA-KEIL is usable as perfect solution to connect gradient areas to levelled floorings for accessible showers where a linear drainage system is used.

Working instructions

Press in the perforated setting leg of BLANKE AQUA-KEIL into the fresh adhesive bed and bring it into the correct position. Then press in the next tiles which have to be moved into to right position so that the top of the profile is flushing with the tiles. Please observe that the tiles have to be layed without any hollows next to the profile. There should be a gap next to the tile of ca. 1,0 - 1,5 mm. The gab has to be filled in completely with mortar.

In case that the profile has to be cutted do it always at the highest point.

For cleaning the stainless steel do not use any steel wool or steel brush. Thereby extraneous rust could occur. Any cleaning agents must not contain hydrochloric acid or chlorine.